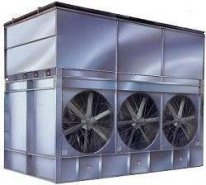

Closed-Loop Evaporative-Type (CE) Cooling System

Resources

A cost-efficient way to maintain consistent equipment cooling temperatures with varying heat loads and environmental conditions. All water-cooled heat-producing industrial processes and equipment will benefit from the installation of this thermostatically controlled heavy-duty (CE) system. That's because it removes heavy heat loads from machines and processes by supplying coolant economically within 10ºF of ambient wet bulb temperatures. Continuously, efficiently and with minimum maintenance.

Completely automatic operation, reliable control of temperature. The system is filled with a low-cost, water/glycol mixture which is continually circulated. Because it is a self-contained system, you won't need to add or change the glycol coolant which prevents freeze problems.

Compact, simple to install. HydroThrift evaporative type cooling systems are two-component systems utilizing a compact pump package and a remote, evaporative type heat exchanger. The pump and control unit is delivered to your site skid-mounted -- piped and wired.

Non-contaminating system extends equipment service life. As a closed-loop system, the HydroThrift CE unit operates cleanly. And that saves production downtime and money. No contaminants, air-borne dirt or chemicals from water treatment as in an open or "once-through" water systems. This will promote long service life for your production equipment because scaling and corrosion in water jackets, coils and heat exchangers are prevented.

Maximum economy of operation saves water, reduces cooling cost and maintains equipment efficiency. The HydroThrift system is designed to provide years of trouble-free service, even in tough environments. The water/glycol mixture is recirculated, permitting economical, efficient cooling. There is minimal need for make-up water to replace the evaporated water in the spray water system. The evaporative loss amounts to about 2 gpm for each 1 million BTU/hr, plus bleed. And you avoid water use regulations and sewer charges related to the discharge of water.

High efficiency operation. The elimination of chemical and dirt build-up on heat exchanger and water jacket surfaces promotes efficiency and minimizes the cost of operation. It saves the cost of heat exchanger repair and maintenance and the associated downtime. Another reason for efficient service is that the coolant temperature is controlled constantly within a limited range, minimizing the costly inconsistencies found in external "once-through" water cooling.

Lowest recycled coolant temperature. The HydroThrift evaporative type cooling system can obtain lower coolant temperatures than dry-type closed-loop cooling systems, since the coolant temperature depends on the ambient wet bulb temperatures.

Engineered systems boost cooling capacity even further. Typical HydroThrift CE type capacities range from 20 to more than 2000 gpm. To achieve even greater cooling capacities for your machine or process, we can engineer systems combining our dry-type and evaporative-type systems.

Closed-circuit evaporative cooler. The evaporative-type heat exchanger utilizes heavy-duty prime surface evaporator coils to circulate the heated process coolant through a cascading water spray. The spray, atomized over coils by an upward air flow, transfers heat quickly and cleanly. A thermostatically controlled pump then recirculates water from the sump to the spray nozzles. Automatic thermostatic dampers provide accurate, continuously varying capacity control. The dampers actuate a limit switch that turns off the fan motors at low ambient and/or low load conditions. Sump heaters are factory installed to prevent sump water freeze-up.

Surge and vent tank. To minimize oxidation of heat transfer surfaces, the ASME code-welded surge and vent tank deaerates the coolant, and includes gauge glass, fill port, drain and vent valves.

System line gauges. Inlet and outlet gauges display pressure and temperature differentials for continuous monitoring of the cooling system.

Automatic control with manual override for reliability and safety. The UL508A designed and manufactured electrical enclosure includes motor controls for the pump and fan motors; off/on selector switch for the system pump motor; and hand/off/auto selector switches for spray pump and fan motors. The 115-volt control circuit interfaces with thermostatically controlled components for automatic operation.

Rugged, close-coupled centrifugal pump provides compact design. Couplings, alignment problems and attendant wear are eliminated through the use of heavy-duty centrifugal pumps close-coupled on the motor shafts. Pumps are equipped with mechanical seals. Pump capacities are typically rated at 100 feet head with higher pump heads available as conditions demand.

Packaged pump and control skid. Pumps, electrical enclosure, vent and surge tank, piping, valves, gauges, and skid wiring are all completely factory assembled on a full-deck fabricated steel base.

Custom engineered. Some projects require custom engineered systems, such as this unit which has an emergency natural gas driven pump to assure uninterrupted coolant flow during a power outage.

Optional equipment. Custom engineering allows a wide-range of options including dual stand-by pumps with automatic switch over, flow switch/alarm circuits, service valves, motor indicating lights, disconnect switches, and trim coolers.

The bottom line is that HydroThrift cooling systems provide continuous, high-efficiency heat transfer. And deliver it at less initial cost and with better payback than other cooling systems.