Closed-Loop Chilled-Water (CW) Cooling System

Resources

A cooling solution for the most demanding equipment cooling requirements and severe environmental conditions. All water-cooled heat-producing processes and equipment requiring coolant supply temperatures below those possible with an evaporative type cooling system or where makeup water is unavailable are candidates for HydroThrift’s industrial chilled water (CW) systems. That's because they remove heat by supplying coolant from -10 to 90 degrees F at the most severe ambient design conditions. Continuously, efficiently and with minimum maintenance.

Completely automatic operation, reliable control of temperature. The system is filled with a low-cost, water/glycol mixture which is continually circulated. Because it is a self-contained system, you won't need to add or change the glycol coolant which prevents freezing. Operation is so simple, no assigned operator is needed. The pump and chiller control package regulates temperature, flow rates and heat exchange indefinitely.

Saves water, reduces cooling costs.The HydroThrift chilled water system is designed to provide years of trouble-free, low-cost service, even in severe, hot environments with explosive hazards. Because the water/glycol mixture is recirculated, economical, efficient cooling is possible. At specified glycol/water mixtures, wintertime freeze-ups won't happen and there is no need for make-up water because there is no evaporation. And you avoid water use regulations and sewer charges related to the discharge of water.

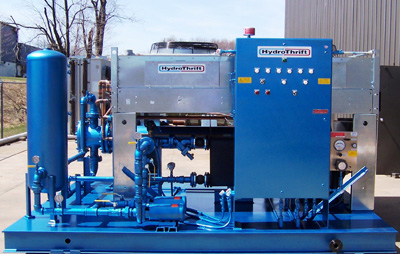

Compact, simple to install. HydroThrift chilled water cooling systems utilize a compact pump package and either a water-cooled or air-cooled industrial chiller. Air-cooled chillers as large as 150 tons have been entirely mounted directly on the pump and control unit, completely charged with refrigerant, piped, and wired. Chillers from 1 to 500 tons refrigeration capacity are available for low, medium, and high temperature applications.

Non-contaminating system extends equipment service life. Similar to all HydroThrift closed-loop cooling systems, the CW system operates cleanly. And that saves you downtime and money. No entrained air, contaminants, air-borne dirt or chemicals from water treatment as in an open type or "once-through" water system. Service life and the efficiency of production equipment are greatly increased because scaling and corrosion on coils, water jackets and heat exchangers are prevented.

Lowest recycled coolant temperature. The HydroThrift chilled water cooling system can obtain lower coolant temperatures than evaporative-type closed-loop cooling systems, since the coolant temperature is provided by a vapor compression refrigeration process rather than an evaporative process limited by ambient wet bulb temperatures.

Engineered systems boost cooling capacity even further. The HydroThrift CW cooling system will be custom engineered to your application requirements for optimum efficiency and maximum cooling capacity. Reciprocating, scroll, or screw refrigeration compressors will be selected to match the process requirements and ambient conditions. Refrigerant evaporators and condensers will be custom designed to operate over the varying capacity and atmospheric requirements. Common, commercial refrigeration components are selected for maintainability despite specialized process requirements.

Water or air cooled chillers. HydroThrift chillers include heavy duty, industrial compressors; multiple condenser options including air-cooled or water-cooled that are mounted locally or supplied for remote installation; shell and tube or brazed plate evaporators; and custom engineered refrigeration control options to accommodate low ambient, high ambient, and variable cooling capacity requirements. Automatic thermostatic controls provide accurate, constant temperatures despite varying cooling requirements and ambient conditions. Custom engineered CW cooling systems are complete with many standard features that other’s provide as options.

Surge and vent tank. To minimize oxidation of heat transfer surfaces, the vent and surge tank deaerates the water/glycol coolant, and includes gauge glass, fill port, drain and vent valves. The CW system tank size is selected to provide an adequate reservoir of chilled fluid and avoid short-cycling the compressor(s) when process heat loads vary.

System line gauges. Inlet and outlet gauges display pressure and temperature for continuous monitoring of the cooling system.

Automatic control for reliability and safety. The UL508A designed and manufactured electrical enclosure includes motor starters for the pump, compressor and fan motors; off/on selector switch for circulating pump motors; and off/automatic selector switch for the thermostatically controlled chiller compressor(s) and fan(s). Indicating lights, intelligent controllers, and multiple alarm options are also common for your custom engineered electrical controls.

Rugged, close-coupled centrifugal pump provides compact design. Couplings, alignment problems and attendant wear are eliminated in HydroThrift cooling systems through the use of heavy-duty centrifugal pumps close-coupled to the motor. Pumps are equipped with mechanical seals. Pump capacities are typically rated at 100 feet head with higher pump heads available as conditions demand.

Packaged pump and control skid. Pumps, electrical enclosure, vent and surge tank, piping, valves, gauges, wiring and safety controls are all completely factory assembled on a full-deck fabricated steel base.

Optional equipment. Custom engineering allows a wide-range of options including stand-by pumps with automatic switch over; stand-by compressors or chillers; alarm indication for low glycol level, low flow, high temperature, chiller monitoring, and motor overloads; service valves; and disconnect switches.

Simple, small chiller applications solved with stock solution.Small, less than 5 refrigeration ton, chillers are typically in stock and available for immediate shipment.

The bottom line is that HydroThrift cooling systems provide continuous, high-efficiency heat transfer. And deliver it at less initial cost and with better payback than other cooling systems.