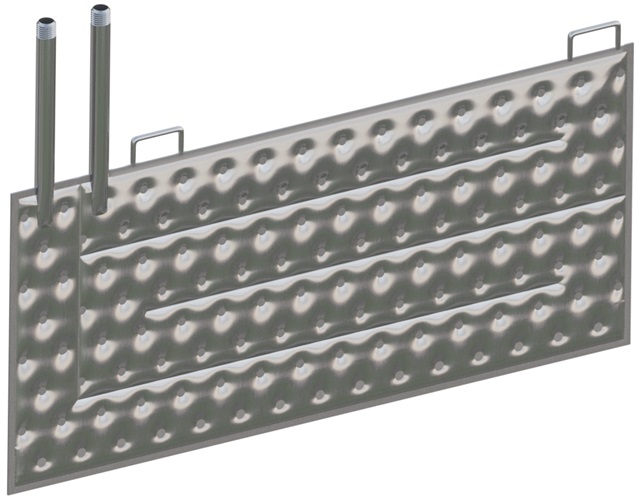

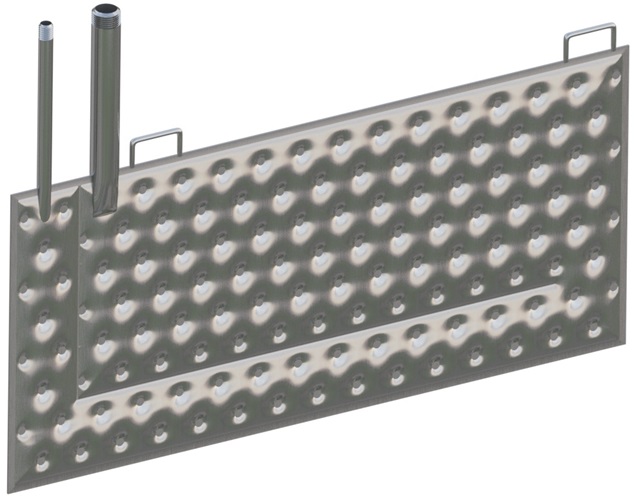

Plate Coil Type 5

The TYPE 5 immersion plate is designed for liquid service. This style of plate is equipped with vertical inlet and outlet nozzles located on the same side.

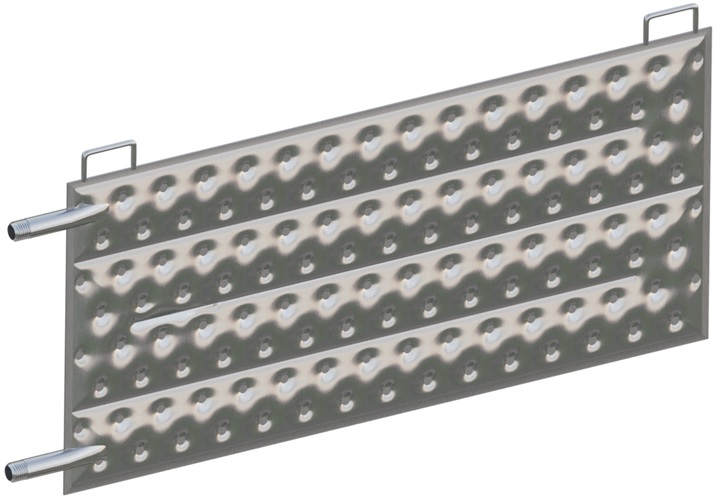

Plate Coil Type 6

The TYPE 6 immersion plate is designed for liquid service. This style of plate is equipped with horizontal inlet and outlet nozzles located on the same end.

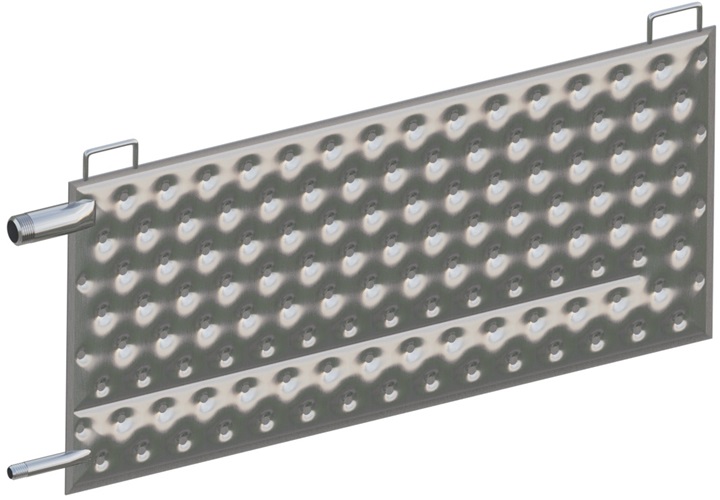

Plate Coil Type 7

The TYPE 7 immersion plate is designed for steam service. This style of plate is equipped with horizontal inlet and outlet nozzles located on the same end.

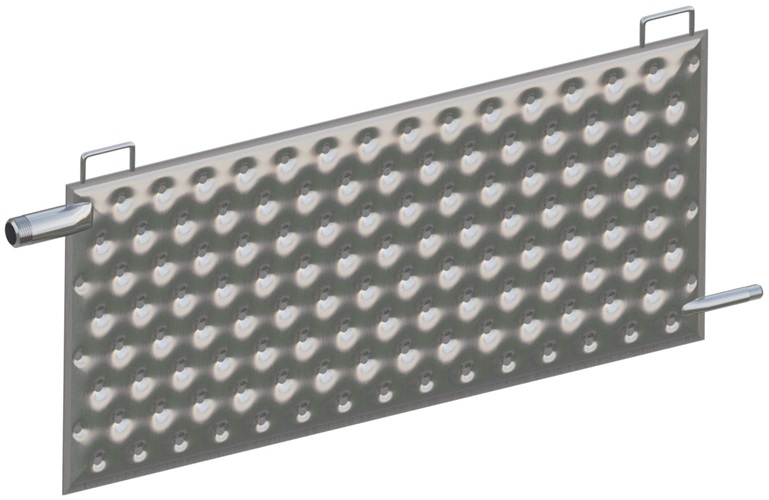

Plate Coil Type 8

The TYPE 8 immersion plate is designed for steam service. This style of plate is equipped with horizontal inlet and outlet nozzles located on opposite ends.

Plate Coil Type 9

The TYPE 9 immersion plate is designed for steam service. This style of plate is equipped with vertical inlet and outlet nozzles located on the same side.

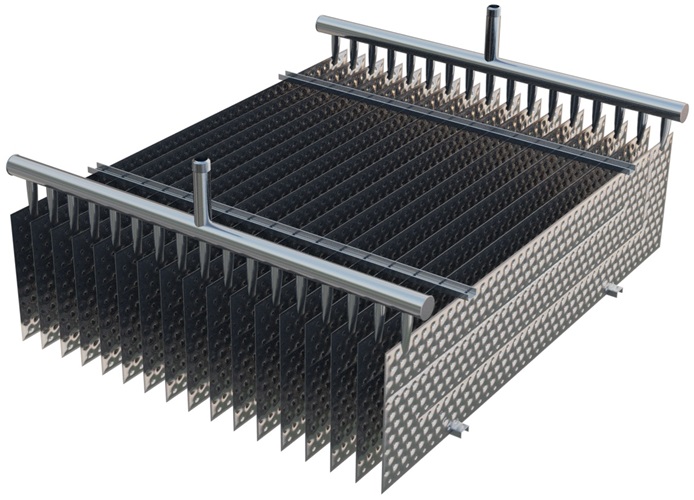

Immersion Banks

The immersion bank arrangement is the most commonly used configuration of the plate bank options. This simple arrangement is designed for submersion into a flooded liquid tank or body of water.

Insertion Banks

Insertion style plate banks are plate banks which are mounted to the outer surface of various process equipment. This is achieved with an integrated mounting face plate, which seals against an opening in the process equipment.

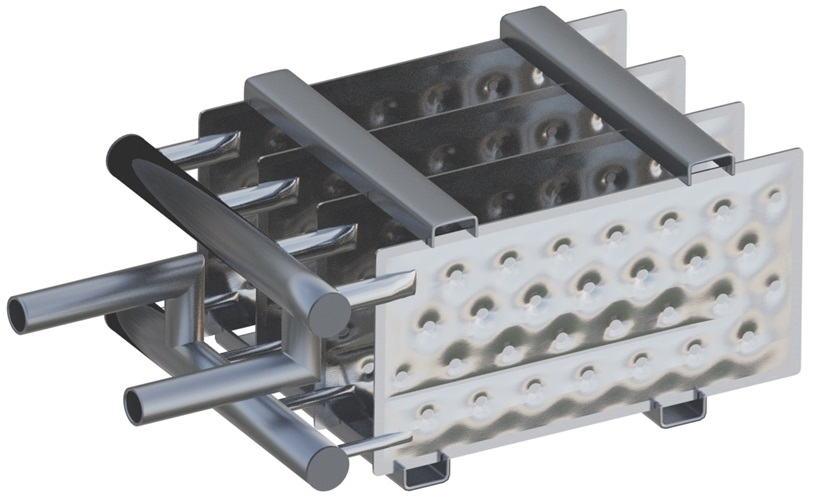

Bayonet Banks

Bayonet style heat exchangers are flange mounted plate bank assemblies. These assemblies are designed to fit through the opening of the mounting flange or manway.

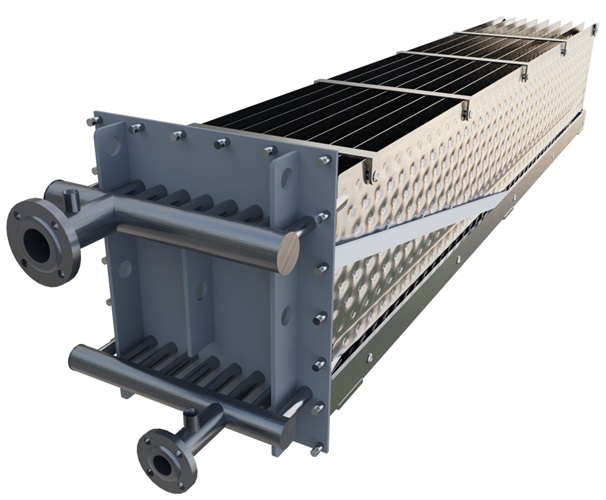

Heat Recovery Banks

Ducted plate banks are commonly used for heat recovery applications where heat can be recovered from hot discharge lines. The integrated duct housing of this assembly simplifies the installation into an existing ventillation system.

Custom Banks

Our engineers are prepared to assist you with the knowledge and experience to properly design a pillow plate heat exchanger for your unique application.

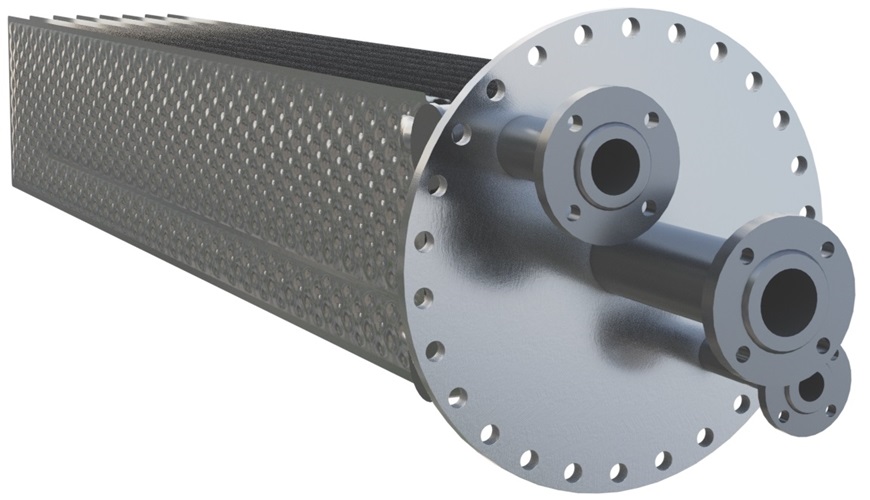

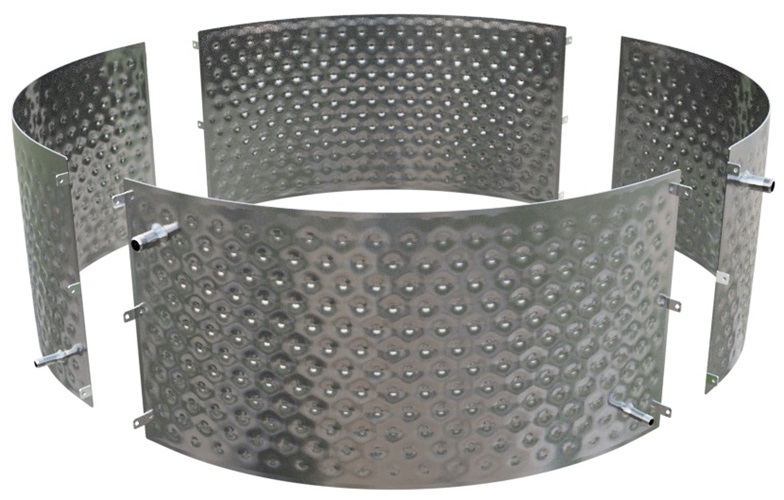

Round Vessel Clamp-On

Curved clamp-on sections are designed to wrap around the circumference of round vessels. The clamp-on sections can be configured in a variety of widths and can be assembled in multiple courses to cover the full cylindrical portion of a vessel.

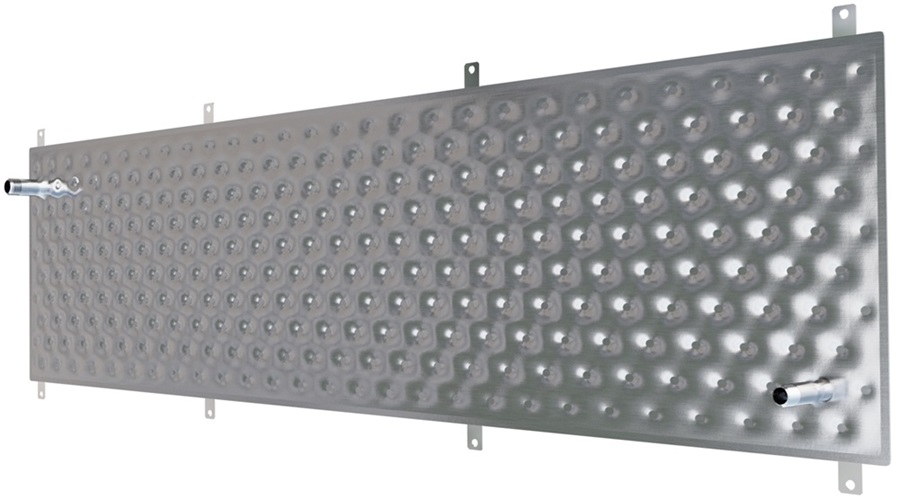

Flat Tank Clamp-On

Flat surface clamp-on plates are equipped with perpendicular mounting hardware allowing the plated to be pressed against its mounting surface.

Tank Components

All surfaces are CNC welded from programs generated directly from our precision CAD drawings. This ensures every part is built to exact dimensions and welding parameters. Our automated welding process allows us full design freedom to optimize our jackets for very complex arrangements and operational conditions.